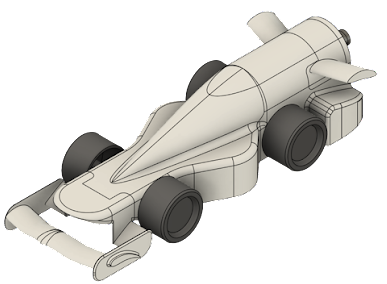

Our Car

One of the crucial components of F1 In Schools is of course the car, so how did we make it and what development has it gone through?

How We Made The Car

Designing a car for the F1 project takes many iterations of brainstorming, prediction, design, and testing. Our process consisted of three main phases: theory, design and test. We initially looked at case studies, previous F1 in Schools cars, and experiences from our entry class season, leading to development of an initial concept. We then produced a CAD model based around the concept, ensuring that the model fully complied to the regulations. After which we would analyse test results and identify where components did and did not meet expectations, areas that needed improving, and where something entirely new may require development.

What We Improved

Development front wing

One of the initial design’s strongest aspects was its front wing. However we still identified opportunities to improve it further. In order to keep inside regulation boundaries, we increased the chord and thickness of the wing, and curved it upwards to permit access to the tether line. The side profile evolved to a more sculptured design, adding material to provide greater support, and the nosecone was lengthened, reducing drag.

Development rear wing

The rear wing was altered significantly. Taking influence from current F1 car design, we opted for a single consistent aero element extending over the rear of the car. This design was found to increase lift and decrease drag simultaneously, making it perfect for our use case.

Final Front Wing

We refined the path of the main aerofoil, revising the angle slightly to direct more air under the car, and create greater lift. We elected to remove the curve on the front wing support structures, to refine airflow over the wheels. The side profiles were also amended, adding fillets to improve strength and facilitate ease of manufacture.

Final Rear wing

Our rear wing was further advanced from the development design, retaining the arch concept but utilising a wider cross section to decrase the wake region whilst making the component easier to produce